| Product | Key Characteristics | Typical Applications |

| PEEK (Polyether Ether Ketone) | – Exceptional thermal stability: Continuous use temp. up to 260°C, Tg≈143°C – Superior mechanical strength (tensile, impact, fatigue resistance) – Excellent chemical resistance to acids, bases, solvents – Biocompatible (complies with ISO 10993) – Low friction coefficient (self-lubricating) | – Aerospace: Engine components, aircraft interior parts – Medical: Surgical instruments, implantable devices, diagnostic equipment – Industrial: Bearings, gears, valves, high-temperature mechanical parts – Electronics: High-heat circuit board components |

| PEKK (Polyether Ketone Ketone) | – Higher crystallinity & heat resistance than PEEK: Continuous use temp. up to 280°C – Outstanding mechanical toughness (stiffness + low-temp impact resistance) – Good processability (injection molding, extrusion, machining) – Inherently flame-retardant (UL94 V-0, no additives needed) | – Aerospace: Structural parts, wire insulation, cabin components – Automotive: High-temperature under-hood parts (e.g., sensor housings) – Electronics: Flame-retardant enclosures, connector components – Oil & Gas: Downhole tools (resistant to high temp/pressure) |

| PPSU (Polyphenylsulfone) | – Exceptional hydrolytic stability (resists high-temp water/steam) – High heat resistance: Continuous use temp. up to 180°C, Tg≈220°C – Superior low-temp impact strength (resists breakage) – Good electrical insulation; compatible with repeated sterilization | – Medical: Surgical trays, dental instruments, baby bottle components – Food Industry: Food contact parts (pumps, valves, containers) – Industrial: High-humidity mechanical parts (e.g., pump impellers) – Electrical: Humid-environment enclosures, insulation parts |

| PEI (Polyetherimide) | – Excellent thermal performance: Tg=217°C, continuous use temp. up to 170°C – Outstanding dimensional stability (low CTE, minimal temp-induced deformation) – Resists chemicals (hydrocarbons, alcohols) & UV radiation – Inherently flame-retardant (UL94 V-0) with low smoke/toxic emission | – Aerospace: Aircraft cabin interiors, wire harness insulation – Automotive: Under-hood electronics, sensor housings – Construction: Flame-retardant interior panels, lighting components – Electronics: High-precision connectors, circuit board supports |

| PSU (Polysulfone) | – Balanced heat/mechanical properties: Continuous use temp. up to 150°C – Excellent transparency (glass-like, for visual inspection needs) – Good chemical resistance to dilute acids, alkalis, organic solvents – Easy machinability (standard metalworking tools for complex shapes) | – Medical: Clear surgical device windows, laboratory instrument housings – Electronics: Transparent insulation parts, LED lighting components – Industrial: Chemical processing equipment (sight glasses, valves) – Consumer Goods: High-temperature-resistant kitchenware, appliance parts |

Comparative Analysis of High-Performance Engineering Plastics: Key Test Results and Material Characteristics by Liebieria Performance

Executive Summary

High-performance engineering plastics have become indispensable in industries such as aerospace, medical devices, and advanced electronics, where traditional materials (e.g., metals, standard plastics) fail to meet stringent requirements for heat resistance, mechanical strength, chemical stability, and electrical insulation. This report presents a detailed comparative analysis of seven leading high-performance polymers—PEKK (Polyetherketoneketone), PEEK (Polyetheretherketone), PPSU (Polyphenylsulfone), PEI (Polyetherimide), TPI (Thermoplastic Polyimide), PSU (Polysulfone), and PESU (Polyethersulfone)—based on standardized testing across five core performance categories: mechanical properties, thermal stability,

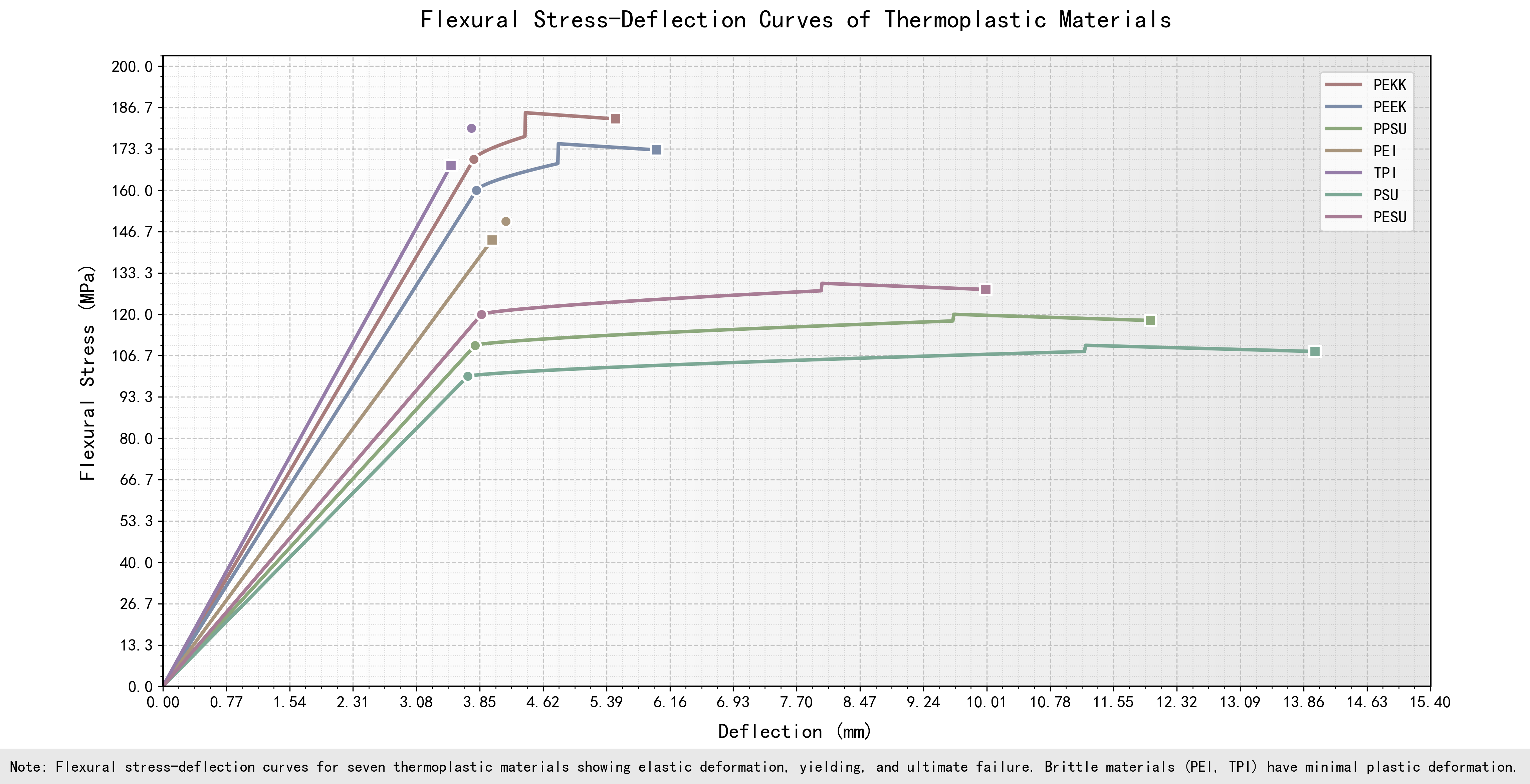

1. Mechanical Performance: Strength, Ductility, and Impact Resistance

Mechanical performance is the foundation of material selection for structural components, as it directly determines a product’s ability to withstand load, vibration, and sudden stress. Testing was conducted in accordance with ISO and GB standards, focusing on tensile, impact, bending, and compressive properties.

1.1 Tensile Properties (ISO 527 / GB/T 1040)

Tensile strength, elongation at break, and elastic modulus are critical for applications like aerospace fasteners or medical device shafts that endure constant tension. Among the seven materials, PEEK stands out with a tensile strength of 90–100 MPa, a distinct yield point, and an elongation at break of 30–40%—a combination that balances rigidity and ductility. This makes PEEK ideal for components requiring both load-bearing capacity and resistance to permanent deformation, such as orthopedic implants.

PEKK closely follows PEEK, with a tensile strength of 85–95 MPa and elongation of 25–35%. Its slightly lower ductility than PEEK is offset by better dimensional stability during processing, making it preferred for 3D-printed aerospace parts where precision is critical. PEI exhibits comparable tensile strength (80–90 MPa) but significantly lower elongation (15–20%), resulting in more brittle behavior. This limits PEI to static-load applications (e.g., electronic enclosures) where flexibility is not a requirement.

PPSU delivers the highest ductility among the group, with elongation at break exceeding 50%, though its tensile strength (70–80 MPa) is lower than PEEK and PEKK. This unique combination makes PPSU suitable for components that need to absorb energy without breaking, such as pediatric medical device housings or industrial connectors. TPI, PSU, and PESU show moderate tensile performance (65–75 MPa, 10–20% elongation), positioning them as cost-effective alternatives for low-to-moderate tension applications like consumer electronics casings.

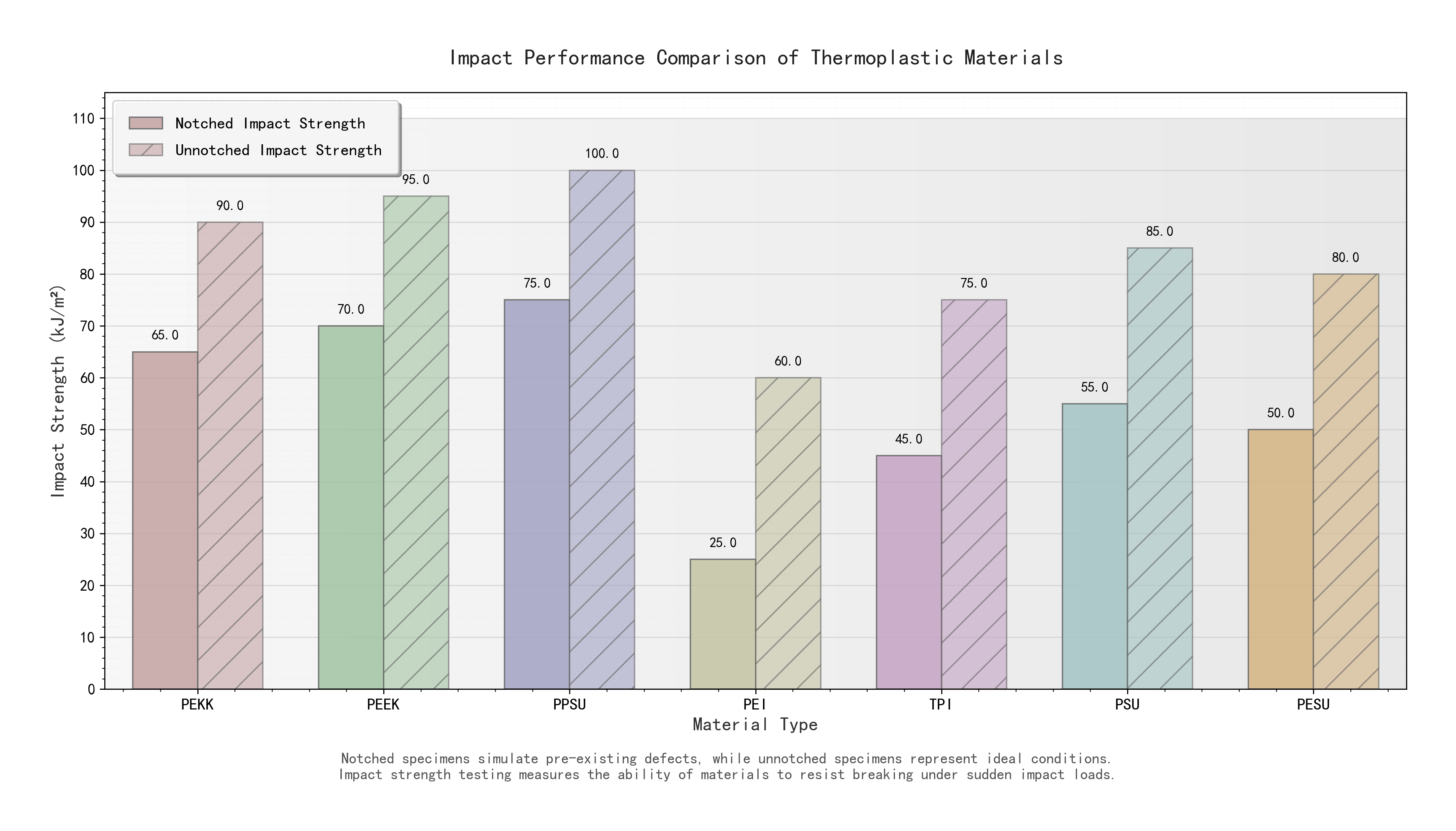

1.2 Impact Resistance (ISO 180/179 / GB/T 1043)

Impact resistance—measured as notched and unnotched impact strength—determines a material’s ability to withstand sudden, short-duration forces (e.g., drops, collisions). PPSU dominates this category, with a notched impact strength of 60–80 kJ/m²—nearly double that of PEEK (30–40 kJ/m²) and three times higher than PEI (20–30 kJ/m²). This exceptional toughness makes PPSU the top choice for medical devices (e.g., surgical instrument handles) and industrial equipment that may experience accidental impacts.

PEEK and PEKK exhibit solid unnotched impact strength (50–60 kJ/m²), but their notched performance drops by ~30%, indicating sensitivity to surface defects. This means they require careful machining to avoid stress concentrations in high-impact applications. PEI and TPI show the lowest impact resistance (20–30 kJ/m² for notched samples), making them better suited for static or low-vibration environments, such as laboratory equipment frames.

1.3 Compressive Strength (ISO 604 / GB/T 1041)

Compressive strength is critical for components under continuous pressure, such as aerospace structural brackets or hydraulic seals. PEEK leads with a compressive strength of 120–140 MPa, followed closely by PEKK (110–130 MPa). Both materials maintain their strength even at 150°C, confirming their suitability for high-temperature compressive applications like jet engine sensor housings.

PEI and TPI exhibit moderate compressive performance (90–110 MPa), which is sufficient for medium-pressure applications such as electrical junction boxes. PSU and PESU have the lowest compressive strength (80–100 MPa) and show significant deformation above 120°C, limiting their use to low-pressure, ambient-temperature scenarios (e.g., consumer appliance components).

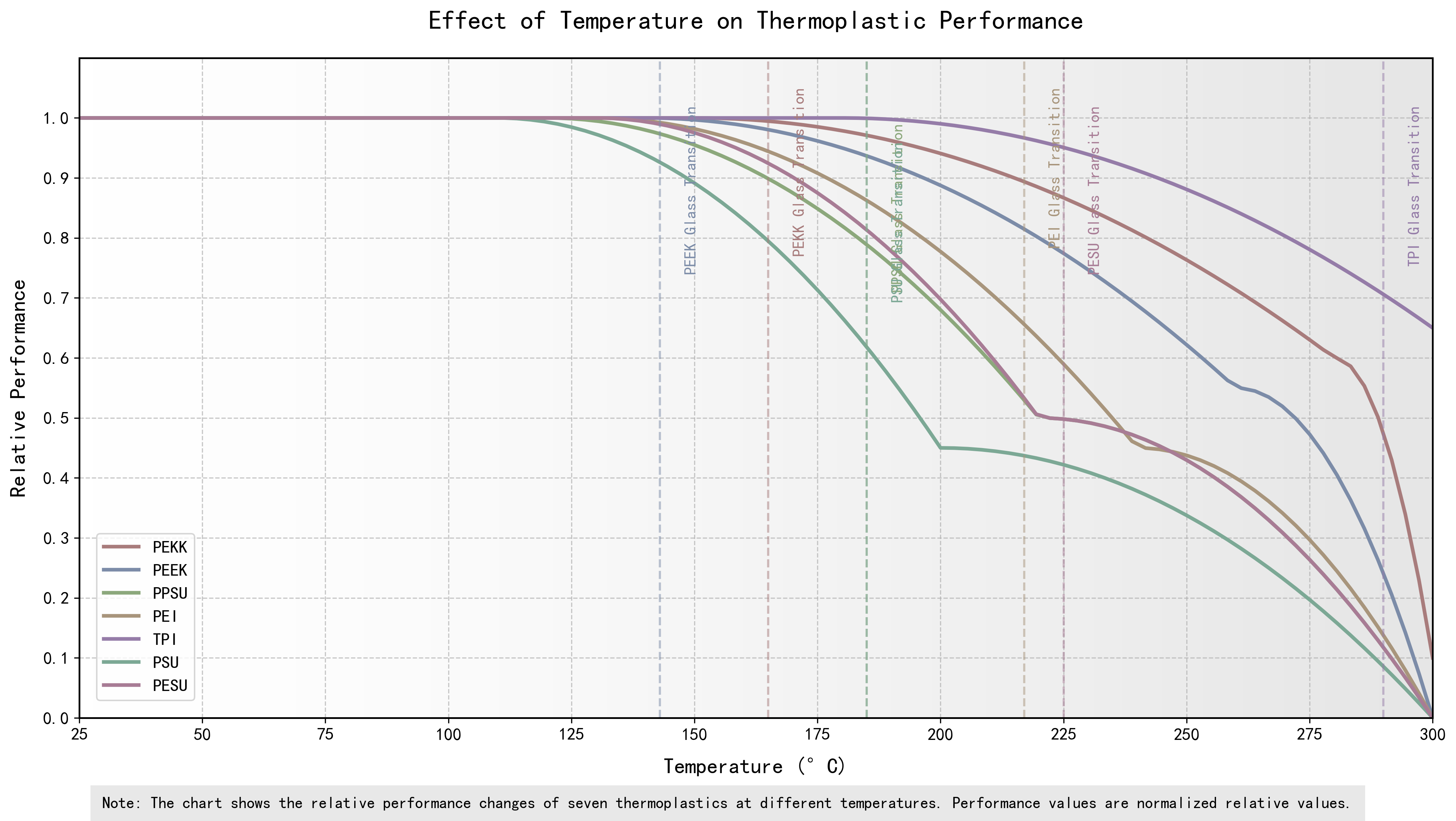

2. Thermal Stability: Withstanding High Temperatures and Thermal Cycling

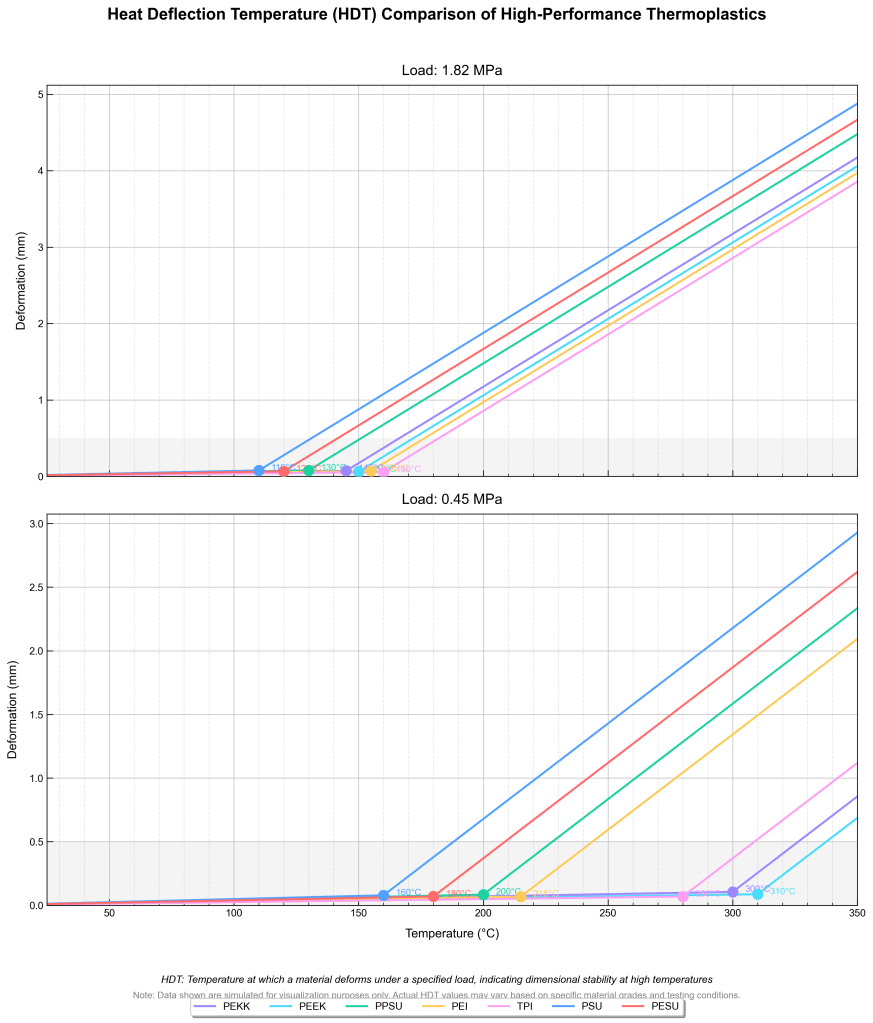

High-performance plastics are often used in environments with extreme or fluctuating temperatures, so thermal stability—measured by heat deflection temperature (HDT), glass transition temperature (Tg), and thermal degradation (TGA)—is a key differentiator.

2.1 Heat Deflection Temperature (HDT, ISO 75 / GB/T 1634)

HDT measures the temperature at which a material deforms under a constant load, indicating its ability to maintain shape in high-heat conditions. Under low load (0.45 MPa), PEEK and TPI excel with HDT values of ~310°C and ~290°C, respectively—making them suitable for aerospace components like engine cowling parts or satellite thermal management systems.

Under higher load (1.82 MPa), PEI shows the most consistent performance, with an HDT of ~190°C (only 20°C lower than its low-load HDT). This stability makes PEI ideal for applications with thermal cycling, such as automotive under-hood sensors that experience frequent temperature swings. PEKK has an HDT of ~280°C (0.45 MPa) and ~160°C (1.82 MPa), balancing high-temperature resistance with load-bearing capacity.

PPSU (HDT ~190°C at 0.45 MPa), PSU (~170°C), and PESU (~180°C) are better suited for medium-temperature applications, such as industrial oven interiors or medical sterilization trays (which operate at ~134°C).

2.2 Glass Transition Temperature (Tg, ISO 11357-2 / GB/T 19466.2)

Tg is the temperature at which a material transitions from a rigid “glass state” to a flexible “rubbery state,” a critical threshold for dimensional stability. TPI and PEI lead here: TPI has a Tg of ~250°C, while PEI’s Tg is ~217°C—significantly higher than PEKK (150–160°C) and PEEK (143°C). This makes TPI and PEI ideal for applications requiring rigidity at elevated temperatures, such as electronic chip carriers (which operate at 180–220°C) or industrial laser components.

PEKK and PEEK have lower Tg values but compensate with better mechanical strength above their Tg, allowing them to maintain functionality in short-term high-heat events (e.g., aircraft engine startup cycles). PPSU (Tg ~185°C), PSU (~180°C), and PESU (~190°C) are suitable for applications below 160°C, where flexibility at higher temperatures is not a concern.

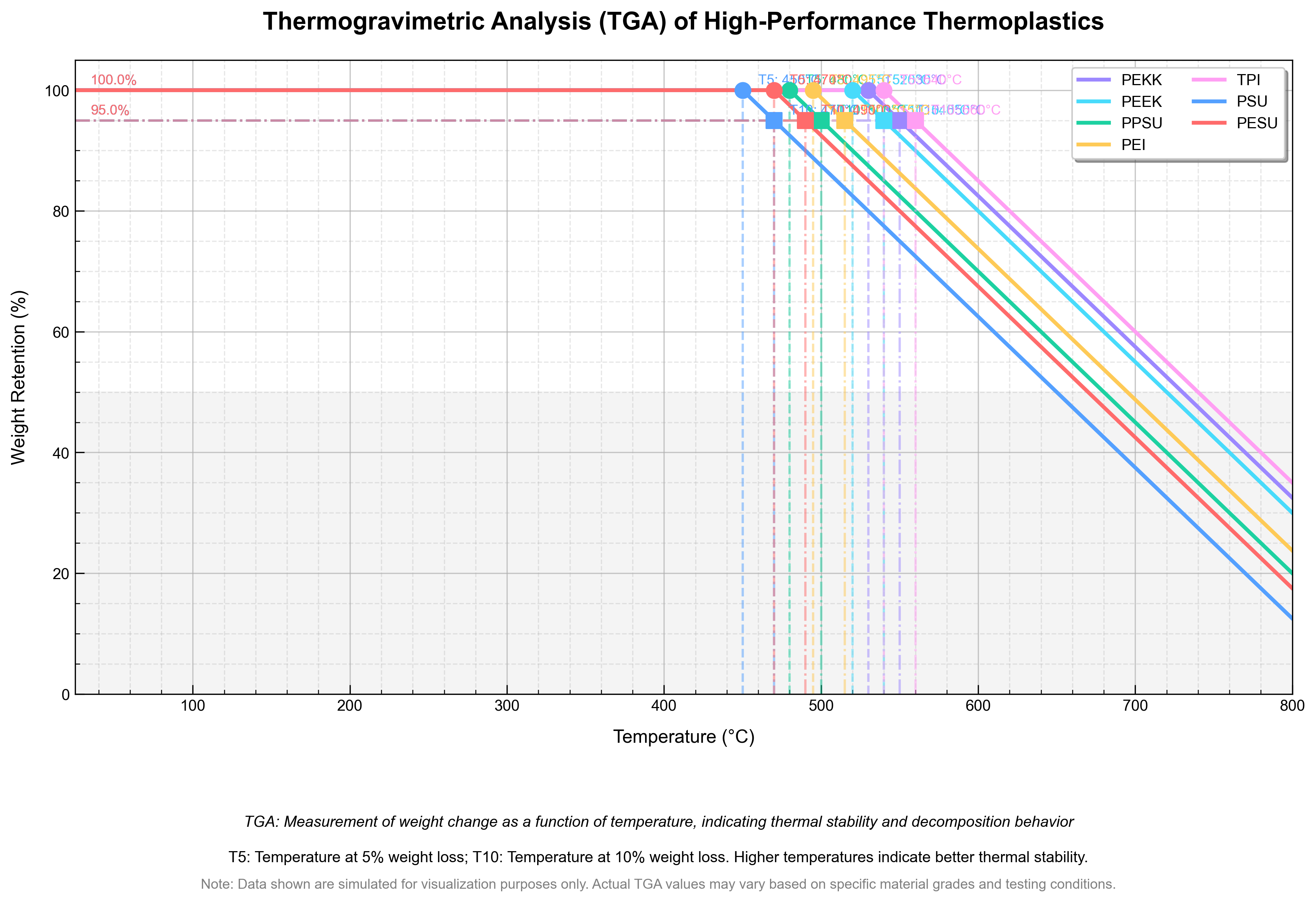

2.3 Thermal Degradation (TGA, ISO 11358 / GB/T 19466.3)

TGA measures weight loss over time at increasing temperatures, indicating a material’s resistance to thermal breakdown. PEEK demonstrates exceptional stability, with 5% weight loss (T5) occurring at ~520°C and 10% weight loss (T10) at ~540°C. This makes it the top choice for applications exposed to prolonged high temperatures, such as rocket nozzle liners or gas turbine components.

PEKK follows closely (T5 ~500°C, T10 ~520°C) and is preferred for applications where processing ease (e.g., 3D printing) is as important as thermal stability. PEI (T5 ~490°C) and TPI (T5 ~480°C) show slightly earlier degradation but still outperform standard engineering plastics. PPSU (T5 ~480°C), PSU (~460°C), and PESU (~470°C) are sufficient for most industrial applications but are not recommended for temperatures above 400°C.

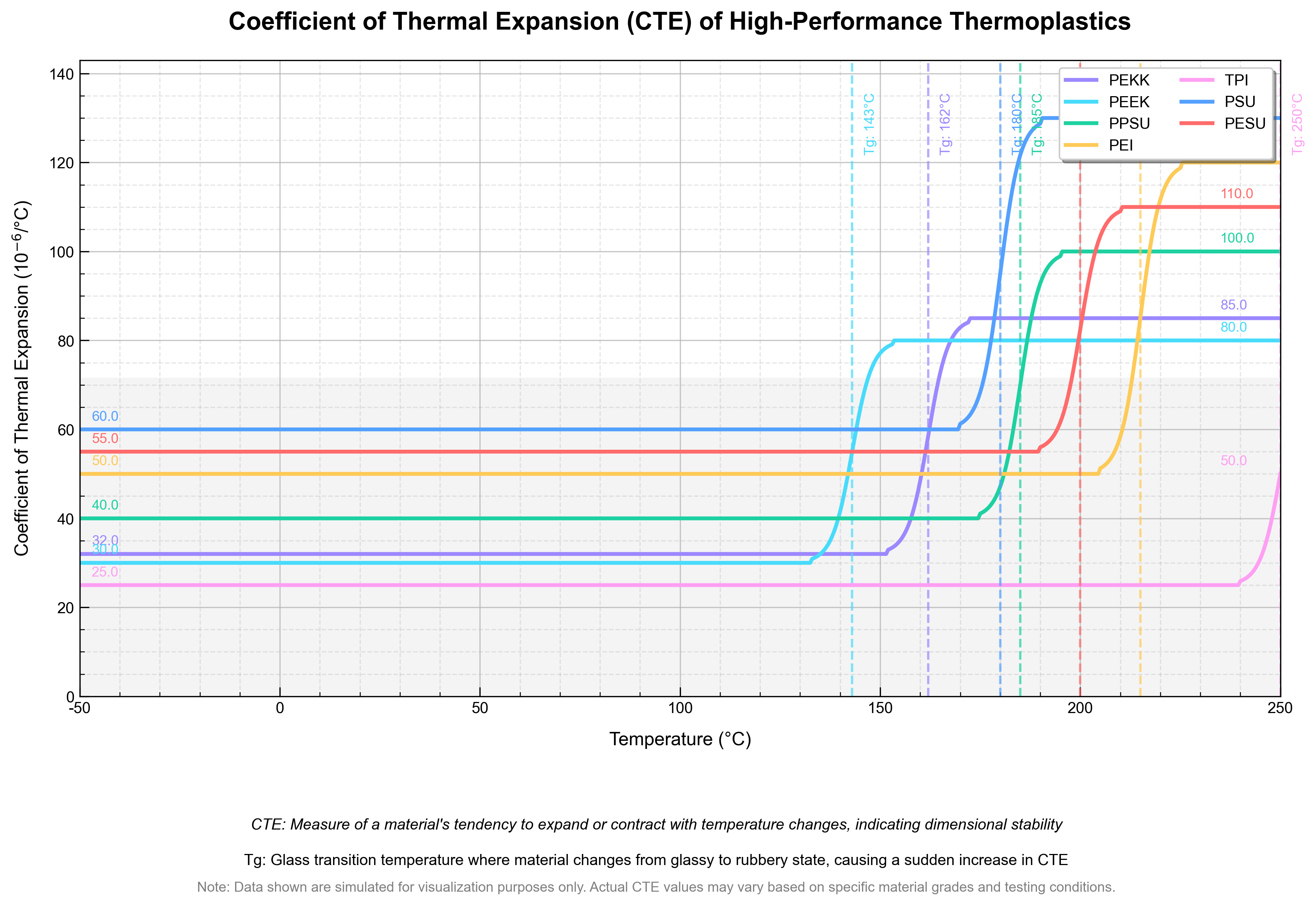

2.4 Linear Thermal Expansion Coefficient (CTE): Introduction and Analysis

The Linear Thermal Expansion Coefficient (CTE) is a critical material property that quantifies the degree of linear dimensional change a material undergoes in response to temperature variations. For high-performance engineering plastics—such as PEEK (polyetheretherketone), PEI (polyetherimide), and PPSU (polyphenylsulfone)—CTE is particularly pivotal, as these materials are often used in applications with frequent or extreme temperature fluctuations (e.g., aerospace electronics, automotive under-hood components, and medical sterilization equipment). A low and stable CTE indicates strong dimensional stability, which prevents component warping, assembly failure, or functional defects under thermal stress.

CTE measurement is standardized globally to ensure accuracy and comparability across materials. The international standard governing CTE testing for plastics is ISO 11359-2, which specifies methods for determining linear thermal expansion using thermomechanical analysis (TMA). In China, the corresponding national standard is GB/T 19466.2, which aligns with ISO 11359-2 in core testing principles while adapting to domestic industry requirements. Both standards prioritize precise control of heating rates (typically 5–20℃/min) and sample preparation, ensuring that CTE data reflects real-world material behavior.

The primary objective of CTE testing under these standards is to map how a material’s linear expansion rate changes with temperature, directly linking to its dimensional stability. Test results are visualized as a CTE Temperature-Expansion Rate Curve, with clear axes definitions:

- The horizontal axis (x-axis) represents temperature, measured in degrees Celsius (℃);

- The vertical axis (y-axis) represents the linear thermal expansion coefficient, expressed in units of 10⁻⁶ per degree Celsius (10⁻⁶/℃) to quantify small expansion magnitudes.

A key characteristic of this curve is its phased behavior, which correlates with the material’s glass transition temperature (Tg)—the critical temperature at which a polymer transitions from a rigid, brittle “glassy state” to a flexible, ductile “rubbery state.”

- Below Tg (Glassy State): Molecular chains in the polymer are tightly packed and have limited mobility, resulting in a low, stable CTE. For example, PEEK—renowned for its thermal stability—exhibits a CTE of approximately 30×10⁻⁶/℃ when temperatures are below its Tg (around 143℃). This low expansion rate makes PEEK suitable for precision components where dimensional consistency is non-negotiable, such as surgical instrument shafts or aerospace sensor housings.

- Above Tg (Rubbery State): As temperature exceeds Tg, molecular chain mobility increases dramatically, leading to a sharp rise in CTE. For PEEK, this transition is striking: above 143℃, its CTE jumps to roughly 80×10⁻⁶/℃—more than double its glassy-state value. This rapid expansion reflects reduced dimensional stability, a factor that must be accounted for when designing components intended to operate above a material’s Tg.

Notably, the shift between the glassy and rubbery states appears as a distinct kink (sudden slope change) in the CTE curve. This kink directly marks the material’s Tg, serving as a critical reference point for engineers. For instance, if a component is designed to operate at 150℃, selecting a material with a Tg above this temperature (e.g., PEI, Tg ≈ 217℃) would ensure it remains in the glassy state, maintaining a low CTE and dimensional stability.

In summary, CTE testing via ISO 11359-2 and GB/T 19466.2 provides actionable data for material selection and design optimization. By analyzing the CTE curve—including phase transitions, Tg identification, and expansion rate magnitudes—engineers can mitigate thermal-related risks and ensure high-performance plastics meet the stringent dimensional requirements of advanced industrial applications.

3. Chemical Resistance: Surviving Corrosive Environments

Many high-performance applications involve exposure to chemicals—from medical disinfectants to aerospace fuels—so resistance to solvents, acids, and moisture is critical.

3.1 Chemical Reagent Resistance (ISO 175 / GB/T 11547)

PEEK and PEKK excel in chemical resistance: PEEK retains 95% of its tensile strength after 500 hours of immersion in 95% ethanol, while PEKK maintains 90% strength in aviation fuel (Jet A-1). This makes them ideal for fuel system components (PEKK) and medical devices that require frequent disinfection (PEEK, e.g., endoscope housings).

PEI shows strong resistance to bases (e.g., 50% sodium hydroxide) but is less stable in strong acids (e.g., 30% sulfuric acid, where strength retention drops to 75%). PPSU is highly resistant to detergents and bleach, making it a staple in medical device cleaning cycles, though it is not compatible with aromatic solvents (e.g., benzene).

PSU and PESU have the lowest chemical resistance among the group: PSU loses 20% of its strength in 10% hydrochloric acid, while PESU degrades in ketones (e.g., acetone). They are best used in mild chemical environments, such as food processing equipment (where exposure is limited to water and mild detergents).

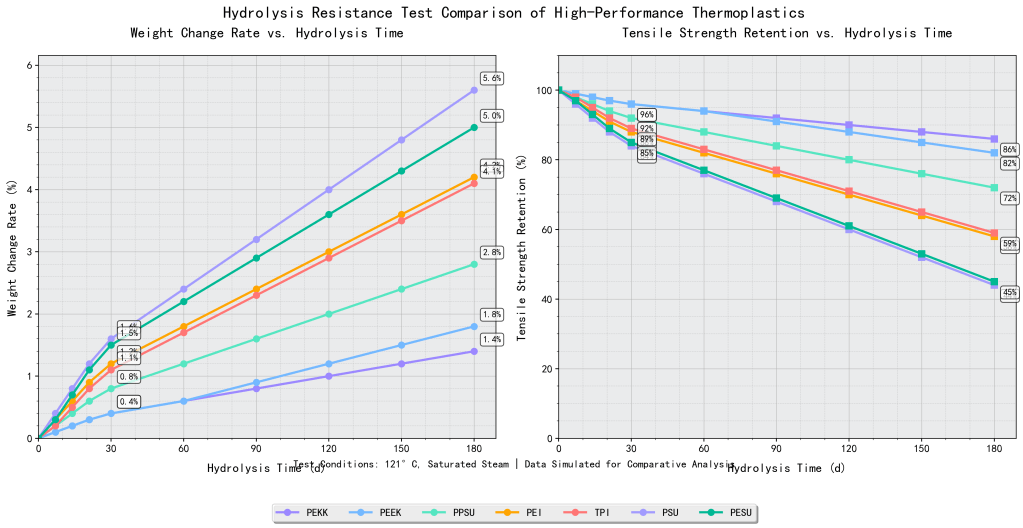

3.2 Hydrolytic Stability (ISO 1879 / GB/T 2570)

Hydrolytic stability—resistance to moisture-induced degradation—is critical for medical devices (autoclaved) and aerospace components (exposed to humidity). PEEK and PEI lead here, with weight changes of <1% after 30 days in 121°C saturated steam (autoclave conditions). This makes them suitable for reusable medical instruments (e.g., surgical forceps) that undergo hundreds of sterilization cycles.

PEKK shows slightly higher weight gain (~1.5%) but maintains 98% of its mechanical strength, making it a viable alternative for less frequent sterilization. PPSU has acceptable hydrolytic stability (~2–3% weight change) but may require design modifications to prevent long-term water absorption. PSU and PESU show the highest weight change (~4–5%) and are not recommended for repeated autoclaving.

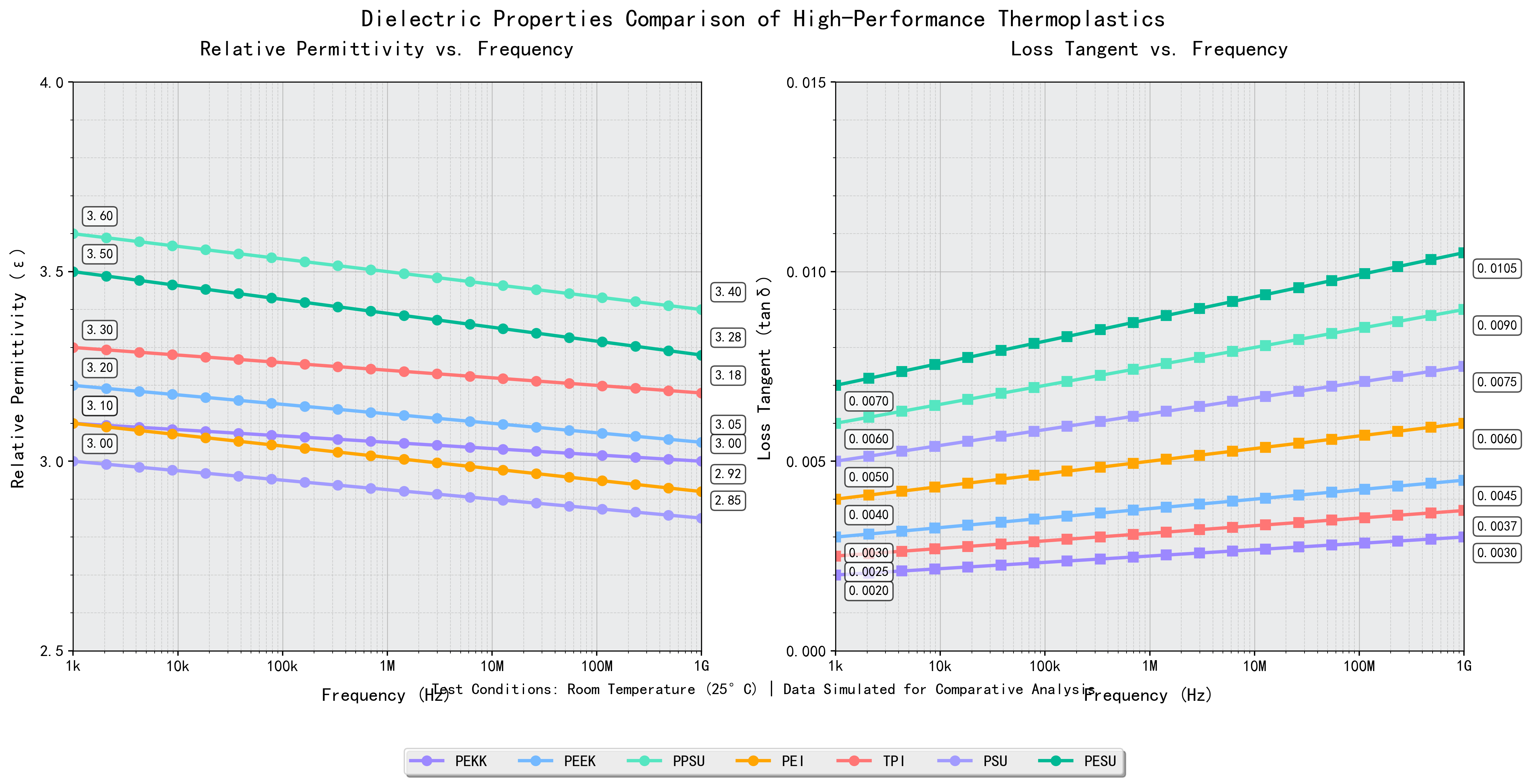

4. Electrical Performance: Insulation and Signal Integrity

In electronic applications (e.g., chip encapsulation, high-voltage insulation), electrical properties—dielectric constant (ε), loss tangent (tanδ), and volume resistivity—are critical.

4.1 Dielectric Constant (ε) and Dielectric Loss (tanδ, IEC 60250 / GB/T 1409)

The dielectric constant (ε) measures a material’s ability to store electrical energy, while tanδ measures energy loss (critical for high-frequency applications). PEI and PEKK have the most stable dielectric properties: PEI’s ε is 3.1 at 1 kHz and 2.9 at 1 GHz, with tanδ <0.001 across frequencies. This makes PEI ideal for 5G antenna components and high-frequency circuit boards, where signal loss must be minimized.

PEEK (ε=2.8–3.0) and TPI (ε=2.9–3.1) also show excellent dielectric stability, suitable for low-loss insulation in power electronics. PPSU (ε=3.2–3.4) has slightly higher capacitance, making it better for capacitor applications. PSU and PESU have the highest ε values (3.5–3.7) and are limited to low-frequency insulation (e.g., household electrical wiring).

4.2 Volume Resistivity (IEC 60093 / GB/T 1410)

Volume resistivity measures a material’s ability to resist electrical current, a key metric for high-voltage insulation. At 200°C, PEKK retains an exceptional volume resistivity of ~10¹⁵ Ω·cm—higher than PEEK (~10¹⁴ Ω·cm) and PEI (~10¹³ Ω·cm). This makes PEKK the top choice for high-temperature electrical components, such as automotive battery insulation or aerospace wiring harnesses.

At ambient temperature, all seven materials have resistivity >10¹⁶ Ω·cm, but PSU and PESU show significant drops (>10¹² Ω·cm) above 150°C, limiting their use in high-temperature electronics.

5. Flammability and Smoke Characteristics: Safety in Fire Events

Aerospace, automotive, and public transit applications require materials that resist burning and produce minimal smoke. Testing was conducted to UL 94 (flammability) and ASTM E662 (smoke density) standards.

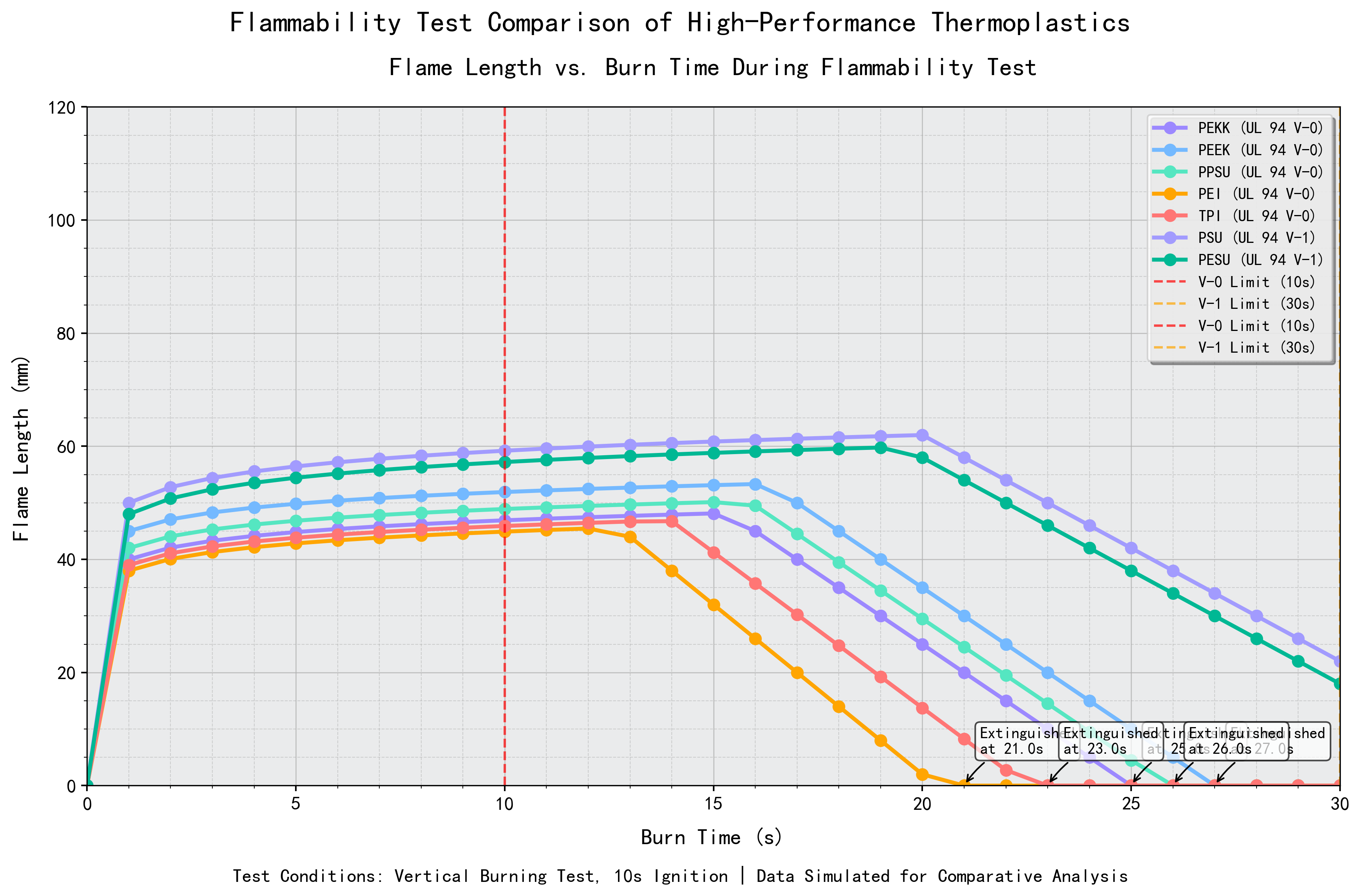

5.1 Flammability (UL 94 / GB/T 2408)

PEI and TPI achieve the highest UL 94 rating (V-0), with flames self-extinguishing within 10 seconds and no dripping. This makes them suitable for aircraft interiors (e.g., cabin panels) and subway components, where fire spread must be contained.

PEEK and PEKK also meet V-0 standards but require thicker samples (>1.5 mm) to avoid dripping. PPSU has a V-1 rating (flames extinguish within 30 seconds), making it acceptable for industrial equipment but not for strict aerospace safety requirements. PSU and PESU have V-2 ratings (dripping allowed), limiting their use to non-critical applications.

5.2 Smoke Density (ASTM E662 / GB/T 8323)

PEEK produces the lowest smoke density, with a specific optical density (Dm) of ~50 after 10 minutes of burning—far below the aerospace limit of 150. This makes it ideal for aircraft cabins and subway tunnels, where visibility during fires is critical.

PEI and PEKK have Dm values of ~70 and ~80, respectively, while PPSU shows higher smoke production (Dm ~120). PSU and PESU exceed the aerospace limit (Dm ~160), making them unsuitable for enclosed public spaces.

6. Application-Specific Recommendations

Based on the test results, each material offers unique advantages that align with specific industry needs:

- Aerospace: PEEK (thermal stability, low smoke) and PEKK (processability, high-temperature insulation) are ideal for engine components, cabin interiors, and fuel systems.

- Medical Devices: PPSU (impact resistance, detergent compatibility) for reusable instrument housings; PEEK (hydrolytic stability, chemical resistance) for implants and surgical tools.

- Electronics: PEI (high Tg, low dielectric loss) for 5G components and high-frequency circuit boards; PEKK (high-temperature resistivity) for battery insulation.

- Industrial Equipment: TPI (high Tg) for high-temperature sensors; PSU/PESU (cost-effectiveness) for ambient-temperature components like pump housings.

Conclusion

This analysis confirms that no single high-performance plastic is universally superior—each material’s strengths (e.g., PEEK’s thermal stability, PPSU’s impact resistance, PEI’s dielectric performance) make it suitable for specific use cases. Product teams must prioritize key performance metrics (e.g., temperature range, chemical exposure, mechanical load) when selecting materials, balancing performance with cost and manufacturability. By leveraging these test results, organizations can optimize product design, reduce failure risks, and ensure compliance with industry standards for high-demand applications.